If you’re venturing into the world of thermal imaging, one of the critical decisions you’ll have to make is choosing between cooled and uncooled cameras. Understanding the differences between these two types of thermal imaging systems can be challenging, but we’re here to help.

Let’s start by defining what these terms mean:

Cooled Thermal Cameras

Cooled Thermal Cameras: These systems house a sensor that operates at very low temperatures, typically below 100K, which equates to about -173 degrees Celsius or -280 degrees Fahrenheit. The cooling mechanism, often involving a Stirling engine cooler, significantly reduces the thermal noise, improving the sensitivity of the camera and allowing for more precise temperature measurements and better image quality.

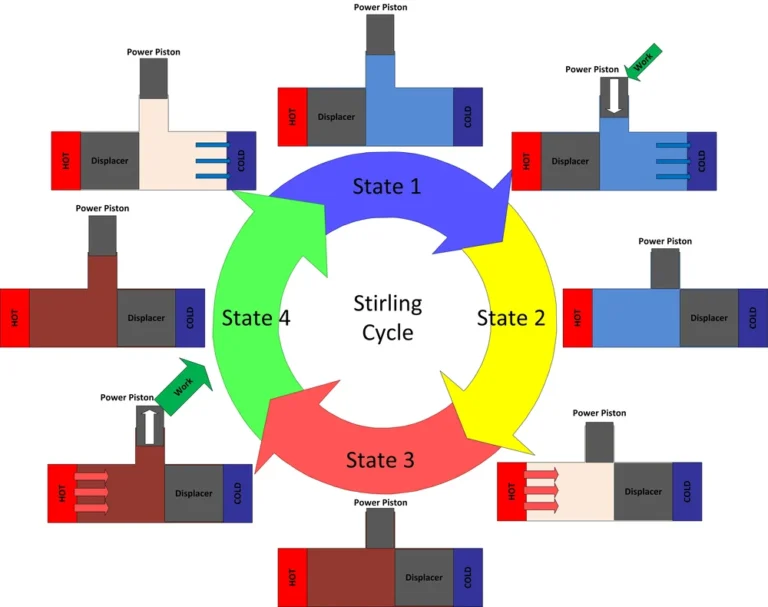

The Stirling engine cooler, also known as a Stirling cycle cryocooler, is a type of cryogenic cooler used to reach very low temperatures, often necessary for the operation of cooled thermal cameras.

The Stirling Cycle

The Stirling cycle involves a series of processes: compression, cooling, expansion, and heating. Here’s a simplified explanation of how a Stirling cooler functions:

- Compression: The cycle begins with a working gas (often helium) inside a cylinder. This gas is then compressed by a piston, causing its temperature to increase due to the principle of pressure-volume work.

- Cooling: The hot, compressed gas is then passed through a heat exchanger, often referred to as a cooler or regenerator, which removes the heat from the gas, causing its temperature to drop.

- Expansion: After cooling, the gas is allowed to expand, which further lowers its temperature. This expansion process absorbs heat energy from the environment, which in the case of a thermal camera, is the sensor that needs to be cooled.

- Heating: After the expansion, the now cold gas passes back through the heat exchanger, which warms the gas back up before it enters the compression stage again. This process ensures the regenerator’s readiness to absorb heat in the next cooling stage.

By continuously repeating this cycle, a Stirling cooler can maintain a sensor at very low temperatures, improving its sensitivity for capturing high-quality thermal images. The Stirling engine cooler, however, does introduce mechanical complexity and additional power requirements, which can lead to higher costs and the need for regular maintenance.

Uncooled Thermal Cameras

Uncooled Thermal Cameras: Unlike their cooled counterparts, uncooled cameras function at ambient temperatures. They leverage a specific sensor technology called microbolometers, which change temperature when exposed to infrared radiation. Although slightly less sensitive than cooled detectors, uncooled cameras offer sufficient performance for many applications.

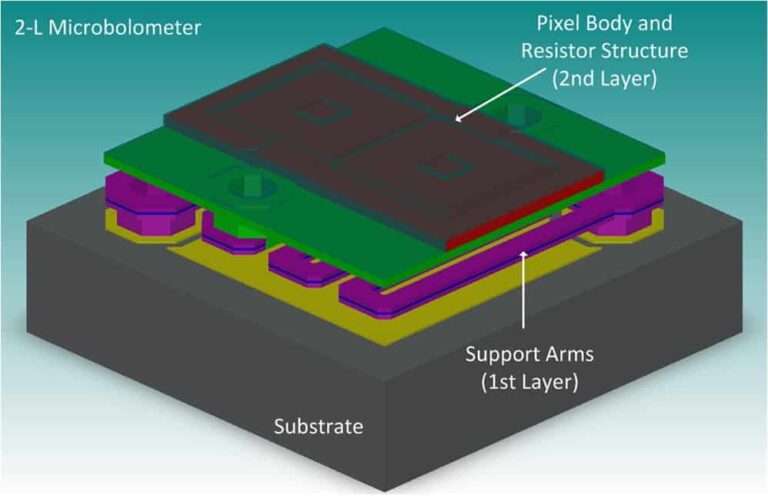

Microbolometers

Microbolometers are a type of uncooled infrared sensor used in thermal cameras. They work by measuring the change in temperature that occurs as a result of absorbing infrared radiation. Here’s a simplified explanation of how a microbolometer works:

- Infrared Absorption: The main component of a microbolometer is a small, temperature-sensitive material that absorbs incoming infrared radiation. This material is typically a resistor made from vanadium oxide (VOx) or amorphous silicon (a-Si). The resistor is suspended on a small structure to insulate it thermally from the surrounding environment, ensuring that it primarily heats up due to the incoming infrared radiation.

- Temperature Change: When the microbolometer absorbs infrared radiation, its temperature rises. The temperature change is proportional to the intensity of the infrared radiation, which corresponds to the temperature of the object being observed.

- Resistance Change: The resistive material in the microbolometer changes its electrical resistance as its temperature changes. Therefore, by measuring the change in resistance, we can determine the change in temperature.

- Readout: The change in resistance is measured and read out by specialized electronic circuitry, and this data is then used to create an image. Each microbolometer acts as a pixel in the final image. The cooler parts of the scene will cause smaller changes in resistance (indicating a lower temperature), while hotter parts will cause larger changes (indicating a higher temperature).

- Image Formation: By combining the data from an array of many microbolometers, the camera can form a complete thermal image of the scene. Software in the camera typically applies a color map to the image to make it easier for a human (or computer) to interpret.

One of the advantages of microbolometers is that they don’t require cooling, unlike some other types of infrared detectors. This makes them more compact, less power-hungry, and more reliable over time, which are all desirable attributes for use in applications like autonomous vehicles, security systems, and industrial inspection.

So, which one should you buy?

It largely depends on your specific needs.

Cooled Thermal Cameras

are typically used in applications that require superior image quality and the ability to detect small differences in temperature, or where long-range detection is necessary. These cameras excel in scientific research, industrial inspections, and defense applications. They’re also favored for surveillance tasks, such as detecting intruders over long distances, due to their higher sensitivity and resolution.

However, cooled cameras have a few drawbacks. They are generally more expensive due to the intricate cooling mechanism, and they require more maintenance, as the coolers eventually wear out and need replacement. Additionally, cooled cameras often have a “cooldown” period when starting up, which could be inconvenient for immediate-use situations.

On the other hand,

Uncooled Thermal Cameras

are more suitable for applications that demand durability, low maintenance, and continuous operation. They’re widely used in firefighting, building inspections, and wildlife observation, as well as in automotive night vision systems and security applications that do not require extreme range or fine temperature differentiation.

Uncooled cameras are usually less expensive and have longer service lives as they lack the mechanically complex cooling system. They’re also “always-on,” meaning there’s no waiting time for the system to cool down before it can be used.

However, the tradeoff is that they typically don’t offer the same level of detail, sensitivity, or range as cooled cameras.

To summarize, your choice between a cooled and uncooled thermal camera will hinge on your specific application, budget, and the level of maintenance you’re prepared to undertake. Cooled cameras provide superior image quality and sensitivity, making them perfect for high-end research, industrial, and long-range surveillance uses. Meanwhile, uncooled cameras, with their durability, lower cost, and “always-on” operation, are better suited for applications like firefighting, building inspections, and wildlife observation.

Whichever you choose, remember that both types of cameras offer the invaluable ability to ‘see’ thermal energy, making visible what is usually invisible to the human eye, and therefore expanding our perception of the world around us.

SPI Corp supplies both thermal cooled and uncooled products. Some of our cameras include the M5 Long Range PTz Thermal camera, M7 Long Rang PTZ Thermal Camera, M9 cooled Long Range PTZ Thermal Camera, and the M11 Ultra Long Range Thermal Camera.

You can check all these cameras out on our www.7b.org website.

The home of our long range cameras. We also have cooled and uncooled gimbal cameras HERE and HERE