As pedestrian fatalities during nighttime rise consistently, global safety and insurance institutions along with regulatory bodies are demanding for a rapid response. Daytime vehicular accidents have seen a decrease due to the integration of cameras and automated braking systems.

However, night vision remains an uncharted territory where these systems don’t offer the same protection. Government and industry regulations are now seeking advancements in nocturnal vision capabilities, with a view to implement suitable technology in a five-year timeline. This swift urgency has turned the auto-industry’s attention to night vision technologies.

Repurposing Defense-Grade Equipment

Previously, attempts have been made to repurpose defense-grade night vision apparatus for automobiles, but they proved to be unsuccessful. This is primarily due to the different operational needs: the military requires image display for personnel while vehicles need images that can be processed by on-board computers.

Repurposing Commercial Equipment

Similarly, commercially used night vision equipment also falls short as it doesn’t meet the stringent demands of automotive electronics, including durability across diverse environments, reliability, cost-effectiveness, and compactness. Cameras in cars are vital safety components that must constantly and accurately feed data to computers, which then make crucial decisions affecting both vehicle occupants and pedestrians.

LLL

Nevertheless, two established night vision technologies have potential for automotive adaptation: low-light-level (LLL) cameras and thermal imaging. LLL cameras, essentially daylight cameras, are modified for low-light conditions.

Their operation can be boosted with image intensifiers or sensors that amplify low light signals internally. However, like their daylight counterparts, they’re impaired by adverse weather conditions and glaring lights.

Thermal Imaging

Thermal imaging, the second night vision technology, leverages a different physics principle: it detects electromagnetic radiation emitted by any object above absolute zero.

This ‘thermal radiation’ is primarily detected in the 8-12 µm long-wave infrared (LWIR) band at room temperatures. Importantly, this band remains clear in atmospheric conditions, allowing for effective imaging.

Cooled vs Uncooled

Thermal imaging relies on image sensors that can transform detected radiation into electrical signals. Currently, there are two types of sensors: cooled sensors that require temperatures below 100K and uncooled detectors with microbolometer structures.

Despite being less efficient than cooled sensors, uncooled detectors are advantageous because of their compact size, low complexity, and satisfactory image data quality. The latter is well-suited for direct viewing as well as computer analysis.

We have an article that goes more in depth about cooled and uncooled sensors here

However, microbolometer cameras face one major challenge: their cost. To adequately detect pedestrians, a camera needs roughly 1000 pixels for wide coverage, which presently translates to thousands of dollars.

However, the advent of automotive regulations and the potential for mass production offers a ripe ground for innovation in the design and manufacture of microbolometer sensors and required optics.

Traditional manufacturing processes for these sensors are expensive: the microbolometer array and signal readout circuitry were fabricated separately and then bonded. Moreover, these signals were analog, needing external digital conversion. The lenses, too, were made from expensive materials like germanium, leading to slow and costly production.

New Age Sensors

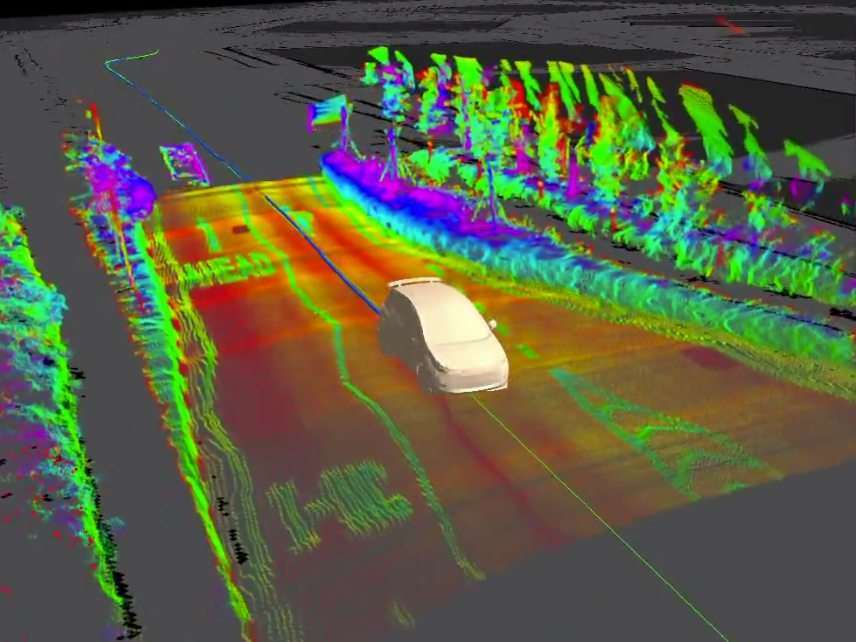

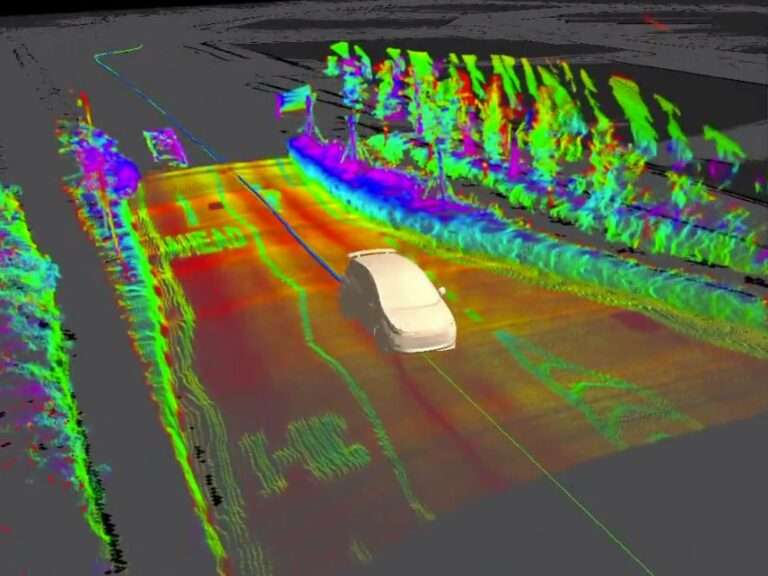

Emerging automotive needs are now overhauling these legacy processes. The new-age sensors have an integrated array and readout system with real-time digitizing and correction capabilities.

Innovative optical materials and methodologies like chalcogenide glasses, metamaterials, diffractive elements, and surface molding are being used to drastically reduce lens cost and size.

These innovations promise a significant change in the design of the cameras. Instead of metal box cameras with multiple connectors, we’re moving towards a single, compact module that can be conveniently installed in vehicles for optimal pedestrian observation.

These modules will connect to an in-car electronic control unit hosting AI-powered convolutional neural networks (CNNs) that can identify and locate pedestrians, even in the dark.

Such a system might seem far-fetched, but successful demonstrations have already been carried out. A 2022 test of a prototype thermal night vision system resulted in the successful automatic stopping of a vehicle when it detected a child-sized dummy stepping onto a poorly lit road, twelve times out of twelve.

This technology has caught the attention of the automotive manufacturing industry and Tier One original equipment suppliers. In the coming year, this system will be ready for mass implementation, bolstering pedestrian safety on the roads.